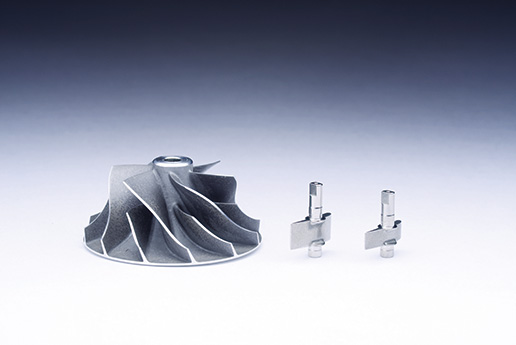

Composite Precision Parts for High-Speed Rotating Equipment/Proposals related to materials

(1)Proposals related to materials

We can propose the most suitable materials that meet part specifications with machinability in mind.

We can also provide information related to inexpensive local procurement abroad based on various needs of customers.

Examples)

・Dental equipment with full titanium body for weight reduction, improvement in durability and strength, and biocompatibility.

・For cost, quality and delivery issues due to surface treatment of aluminum or brass: eliminating surface treatment using stainless steel such as SUS303,.SUS304 or SUS316.

・Reduction of lead time and cost by procuring locally, abroad (A6061,.SUS303/SUS304,.C3604B,.etc.)

Composite Precision Parts for High-Speed Rotating Equipment/Proposals related to Surface treatment

(2)Proposals for design machining, appearance and surface treatment

We can make proposals to meet your requests for the shape of the outer diameter, milling,.slit design, finished roughness, luster; gloss and/or sense of magnificence.

We can also propose a beautiful appearance to enhance the value of the product brand.

Examples)

・Creating a smooth appearance for joints between the outer diameter radius and another radius.

・Finishing with the minimum of machining traces,. even for slits and wrench flats.

・Finishing to make joints between parts least noticeable.

Composite Precision Parts for High-Speed Rotating Equipment/Proposals related to durability

(3)Proposals for manufacturing methods related to durability and/or strength

We can propose high spec shafts and/or bearings using materials,such as S45C, SUS416,SUS 420j2 or SCM415,to meet the required hardness between HRC18 and HRC 62.

Examples)

・For cost, quality and delivery issues due to surface treatment of aluminum or brass: eliminating surface treatment using a heat-treated material such as SUS416, SUS420j2 or SUS440.

・lmproving durability by changing from SUS416 to SUS420j2.

・Controlling to minimize hardness variation.

Composite Precision Parts for High-Speed Rotating Equipment/Proposals related to manufacturing methods (machining methods)

(4)Proposals for unibody manufacturing methods (machining methods)

We can propose machined parts with high accuracy, high rigidity and low cost made by the one and only manufacturing method using CNC3 series complex lathing machines, 5-spindle machining centers, or unique machining jigs and tools.

Eliminating parts to be assembled can increase strength and flexibility in housing strength design.

Moreover; we can provide such products with beauty and accuracy.

Examples)

・Finishing of molded materials →Cost can be reduced and rigidity and accuracy can be improved by machining to shape.

・Quality variation in machining due to variation in molded materials→lt can assure total quality.

・Lack of management of the molded material inventories in production control →lt can reduce lead time through a coherent production control of materials and machining.

Composite Precision Parts for High-Speed Rotating Equipment/Proposals related to machining

(5)Proposals for prototyping and mass production of special shapes using difficult-to-cut materials or special specs

There is much tacit knowledge in parts manufacturing. We manufacture parts that completely satisfy required specs with our experience and technologies backed by our intuition.

ln reality, we sometimes face shapes or specs that we have never encountered before. ln such cases, we utilize our existing know-how and principles for standardization and leveling so that we will be able to absorb the experience as our new know-how upon completion.

Our accumulated know-how sets a difference from the competitors and it is the core of our technical competitiveness.

Examples)

・Machining of long and thin parts with an irregular shape

・Finishing with a roughness of Ra 0.2 or less

・Machining of cylindrical parts with a 0.1 mm tip inner diameter

Composite Precision Parts for High-Speed Rotating Equipment/Proposals related to quality

(6)Proposals for machining and measuring high spec parts

with geometric tolerances, such as circularity, concentricity or cylindricity

lt is necessary to investigate many factors, such as manufacturing processes, machines to use, jigs,.tools,.measuring devices and measuring methods,. to meet the geometric tolerances required for complex machined parts or high spec parts.

These must be compliant with customers' specifications.

We vigorously work toward customer satisfaction by meeting the strict quality requirements of medical device manufacturers and automotive manufactures,. and we make proposals based on such experiences.

Examples)

・Concentricity,circularity,cylindricity and perpendicularity of high-speed rotating equipment

・Specification requirements of bearings for precise moving devices

・Geometric tolerance of bearing inner diameter

Composite Precision Parts for High-Speed Rotating Equipment/Proposals related to international production and/or procurement

(7)Proposals related to production,. procurement,.establishing and/or operating a company in vietnam.

lnternational procurement includes part designs, materials, machining,surface treatment,heat treatment, polishing, grinding and assembly.

Our strength is that we manage our localized plant. We make sure to explain fundamental proposals for practical business, including advantages and disadvantages, to our customers.

We have grown to be delegated to operate a plant by a device manufacturer in 2013.

Examples)

・Supplying parts for medical equipment abroad

・Selling mass-produced impellers for turbochargers locally

・Manufacturing and selling jigs, tools and cutters locally